universal carrier masterbatch FTM-169 application in PET

PET is a semi-crystalline thermoplastic saturated polyester prepared by transesterification of dimethyl terephthalate with ethylene glycol or esterification of terephthalate with ethylene glycol, and then polycondensation reaction. Because PET molecules contain flexible chain segments, difficult activities of benzene rings and polar ester groups, this gives PET a lot of excellent properties, such as the PET molecular chain of high geometric regularity and greater rigidity, it has a high mechanical strength, outstanding chemical resistance, heat resistance and excellent electrical properties; There is no side chain in the molecule, the structure is symmetrical, to meet the requirements of compact packing, so that it has a high degree of crystallization and high melting point. However, the molecular structure of PET also determines its high glass transition temperature, slow crystallization rate, long molding cycle, large molding shrinkage, poor dimensional stability, brittleness, poor heat stability and other defects, so that PET is limited in application.

Universal carrier masterbatch FTM-169 is based on resin with high polarity as the carrier, combined with talc powder and additives in a certain proportion, and made into high filling carrier masterbatch through granulation. It has good compatibility, good temperature resistance, environmental stress resistance, excellent enhancement and toughening and nucleation promotion effect. Can be widely used in processing temperature above 240℃ high temperature material, polar resin, namely PET, PBT, PA, PC, ABS, PC/PBT, PC/ABS, etc.

Therefore, in this paper, through the design of pure PET resin (blank sample), only addition of talc, compound addition of 5% toughening agent and talc and simple addition of FTM-169 four system formula, the latter three formula have the same proportion of powder filling, testing the bending modulus, cantilever beam gap impact strength, shrinkage and thermal deformation temperature, And compare the performance differences of these four systems.

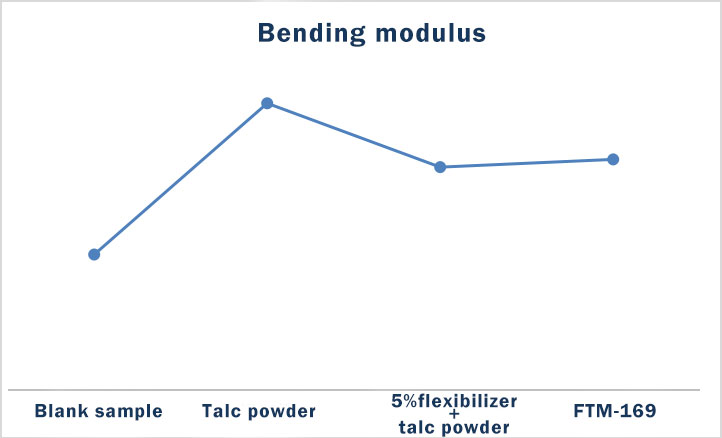

The difference of bending modulus of four systems

Figure 1 Bending modulus of the four systems

As can be seen from Figure 1, FTM-169 has a higher bending modulus than the system with 5% toughening agent added. At the same time, compared with pure PET resin, the bending modulus is also significantly improved, indicating that FTM-169 has a high modulus.

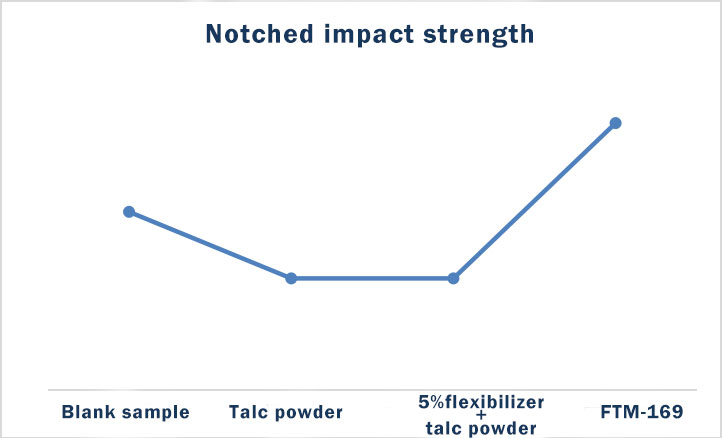

Difference of notched impact strength of cantilever beam of four systems

Figure 2 Notched impact strength of cantilever beams of four systems

It can be seen from Figure 2 that FTM-169 has the highest notching impact strength of the cantilever beam among the four systems, which indicates that FTM-169 has excellent toughening effect in PET.

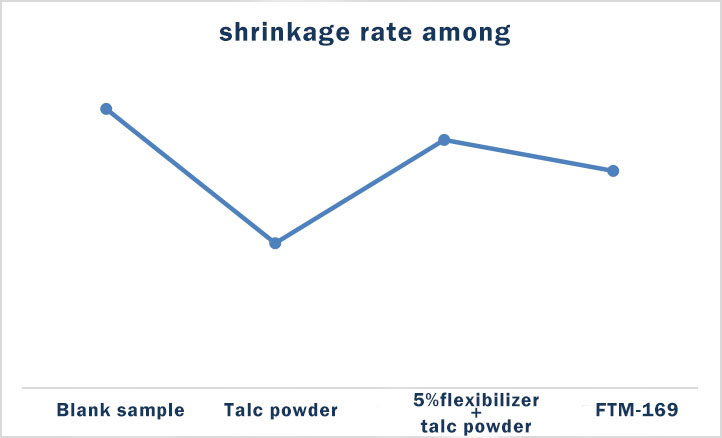

The difference of shrinkage rate among the four systems

Figure 3 Shrinkage rates of the four systems

As can be seen from Figure 3, compared with the system with 5% toughening agent, FTM-169 has a lower shrinkage rate. At the same time, compared with pure PET resin, FTM-169 also has a significant reduction in shrinkage rate, which indicates that FTM-169 has good dimensional stability in PET.

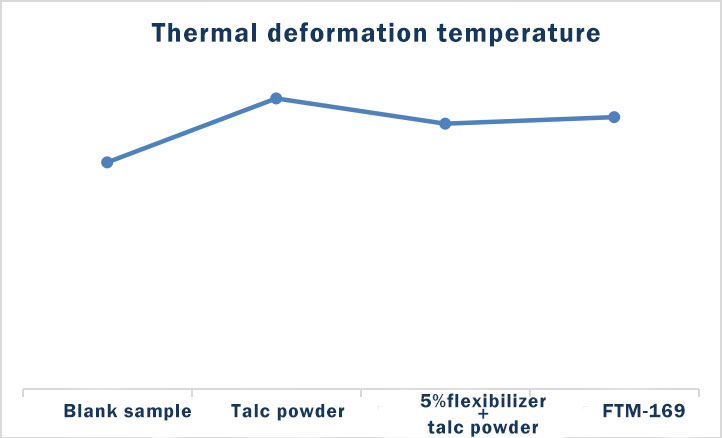

Thermal deformation temperature difference of four systems

Figure 4. Thermal deformation temperature of the four systems

As can be seen from Figure 4, FTM-169 has a higher thermal deformation temperature than the system with 5% toughening agent added. Meanwhile, compared with pure PET resin, FTM-169 also has a significant increase in thermal deformation temperature, indicating that FTM-169 has good thermal stability in PET.

Conclusion: Universal carrier masterbatch FTM-169 plays a good toughening effect in PET polar resin. Compared with other toughening agents, it also has the characteristics of high modulus and low shrinkage, and improves the dimensional stability of the product.

Xuefeng powder is committed to the research and development, production and sales of talc, calcium carbonate and other inorganic powder, welcome customers and friends to call exchange, Xuefeng powder wholeheartedly for your service!