Types of color fillers and factors affecting color spreading

With the development of science and technology, the improvement of people's living standards, the pursuit of color aesthetics, color blending has become increasingly important. Color mixing technology is used in all aspects of our life, such as coatings, inks, printing and dyeing, plastic products, paper, rubber products and ceramics and other industries, and with the rapid development of downstream industries, the demand for color fillers is expanding.

Color filler is actually divided into pigment and filler: pigment is a class of colored micro-fine granular substances, its particles to show the color of a class of inorganic or organic substances, it has a covering power, coloring power, commonly used in the preparation of coatings, inks, and coloring plastics and rubber, so it can also be called coloring agents; filler is a class of micro-fine granular substances in the medium to fill the main role, the appearance of dry powder is mostly white or light gray Generally, its effect on the medium is more limited in terms of covering power and elimination of color. By adding fillers to the medium, the physical and chemical properties of the non-color properties of the medium can be effectively changed; therefore, the fillers are also known as body pigments.

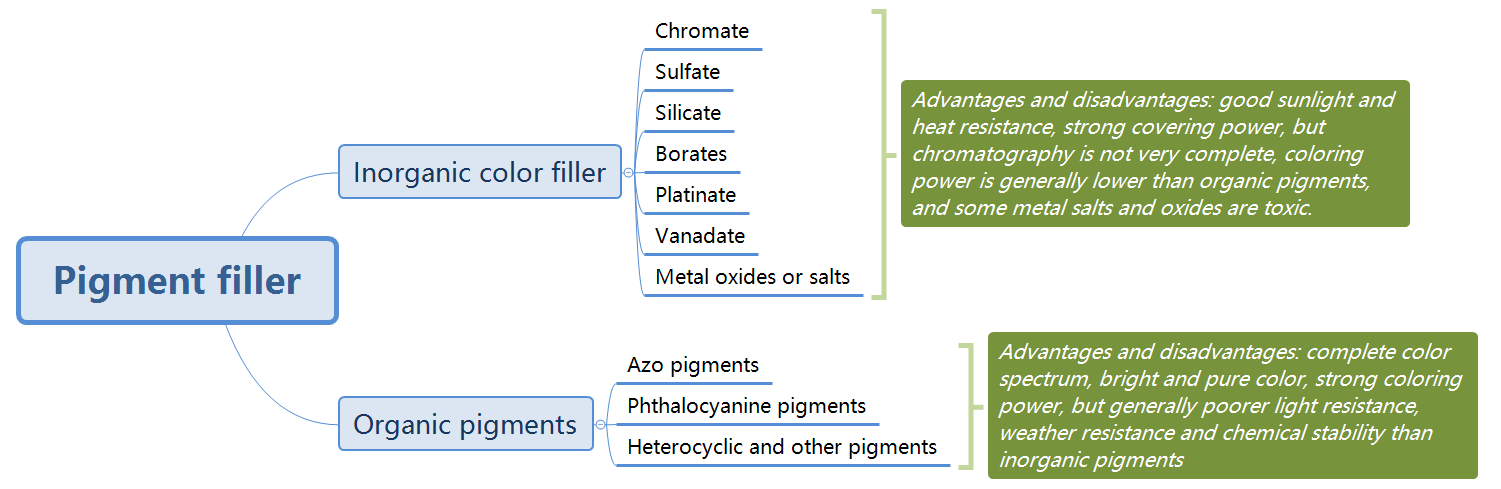

In this paper, we will collectively refer to both as color fillers for the sake of uniformity; the color fillers can be classified in the following manner.

Classification of pigments | |

Chemical composition | Inorganic pigments and organic pigments |

Performance and function | Color pigments, metallic pigments, functional pigments, body pigments (fillers) |

Production Titanium | iron, chromium, lead, metallic and organic synthetic pigments, etc. |

Application angle | Pigments for paint, ink, plastic, rubber, medicine and cosmetics, etc. |

The evaluation of general color fillers can be evaluated from various aspects such as color phase, coloring power, covering power, heat resistance and weather resistance.

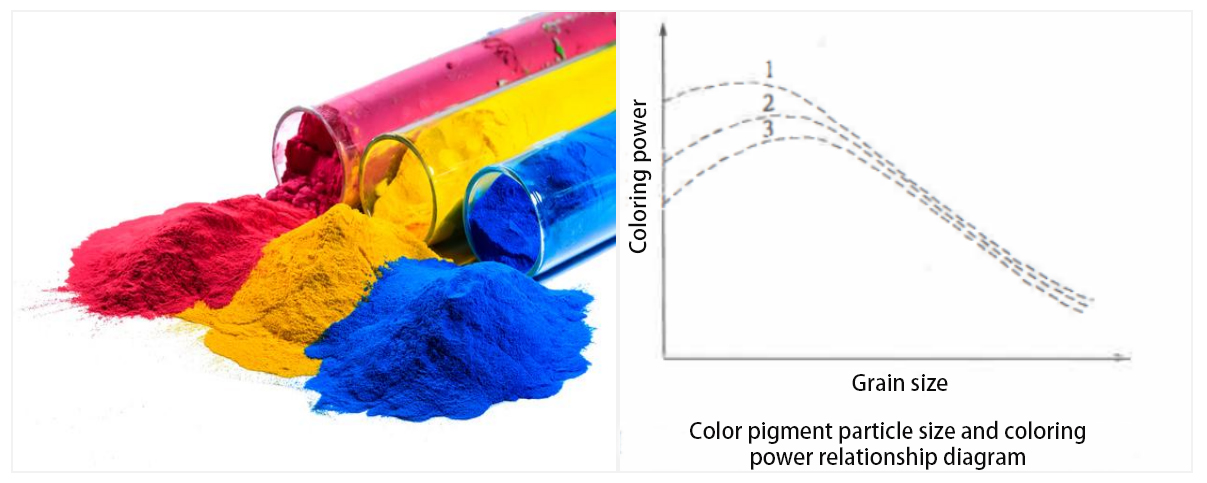

Coloring power of coloring pigment: the ability of a pigment to show the color strength after mixing with another benchmark pigment, usually white pigment is used as the benchmark to measure the coloring power of various color or black pigments; generally the greater the coloring power of pigment, the smaller the amount of coloring agent, the lower the coloring cost; the coloring power generally increases as the particle size of pigment decreases, when the particle size decreases to a certain degree, its coloring power will decrease due to the decrease of particle size Therefore, there is the best particle size to make the coloring power stronger.

In contrast to the pigment coloring power, there is also the achromatic power of color filler: achromatic power refers to the ability of one color pigment to offset the color of another pigment, and is usually used to evaluate the ability of white color filler to lighten the color of coloring pigment. Generally, if the color filler has a larger refractive index, it has a higher achromatic power.

Covering power of color filler: The minimum pigment required to cover the black and white grid of the substrate is called the covering power, which is usually characterized by the mass of dry pigment per square meter of the substrate, expressed in g/m2. The general covering power is caused by the difference between the refractive index of the color filler and the presence of its perimetric medium. When the refractive index of the color filler and the base material are equal, it is transparent, when the refractive index of the color filler is greater than the refractive index of the base material, the greater the difference between the two, the stronger the covering power is.

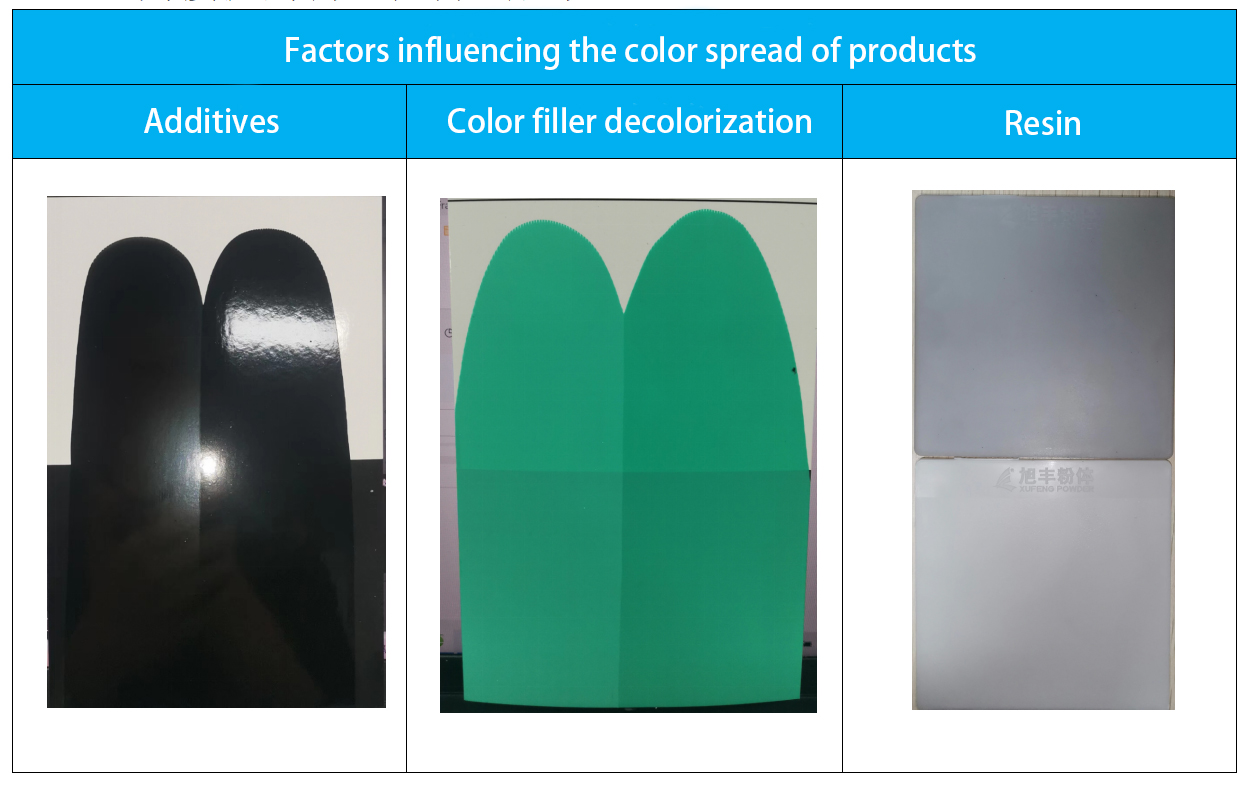

The above are the main evaluation points of color filler. In life, coloring pigments are often used in the development and design of various colors of coatings, inks, plastics, etc., which usually involve color matching and color mixing at this time; the coloring pigment's spreading colorability in products is generally affected by factors such as resin, additives, white color filler's achromatic power, etc.; these factors are generally easy to be ignored as the base material when color mixing, but these factors These factors are usually neglected in color mixing, but these factors will usually cause the addition of color powder or color paste in excess, which will indirectly increase the cost of color mixing and products.

The above figure shows the color contrast effect of black and green pigments in common inks, emulsion paints and modified plastic products, the color difference caused by the difference of additives, color fillers and base material resin; this situation to a certain extent increases the subsequent color mixing production cost, and at the same time, with the increase of the coloring pigment addition ratio but not enough resin to protect its coating, it may further cause the light resistance, weather resistance of the products, In the production and preparation of colored products, we can use white pigment fillers with low color loss and excellent compatibility to achieve excellent color development with cost reduction and efficiency.