Synergistic effects of ultrafine talc and fumed silica in coatings

In the debugging of coating and primer formulations, in order to guarantee the stability of product storage and construction, the flatness of the coating surface, and to improve the performance of the coating in terms of heat, chemical and corrosion resistance, and at the same time to effectively control the cost, it is common to use two or more kinds of powders in the debugging mode, and generally there is a debugging mode using ultra-fine talcum powder in synergistic collocation with fumed silica in order to satisfy the technical requirements for the finished coating products. Requirements.

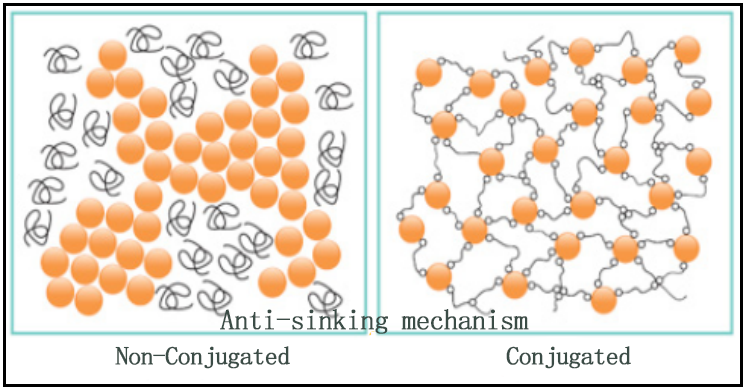

Fumed silica is often used as rheological additives in coatings and printing ink, and also has the functions of anti-settling, anti-caking, matting and physical anticorrosion; there are a large number of silanol bonds on its surface, which can form hydrogen bonding with itself or with the substrate to form a similar network-like structure, which can play a better role in stabilizing the pigment or other fillers to support the role of preventing it from settling or clumping. At the same time, the high oil absorption value of pyrogenic silica has obvious thickening effect, choose the right type of pyrogenic silica, a small amount of addition can effectively improve the viscosity of the coating, increase the pigment or filler in the stabilization of the cycle of the resistance to precipitation, and play the effect of antisinking or preventing agglomeration.

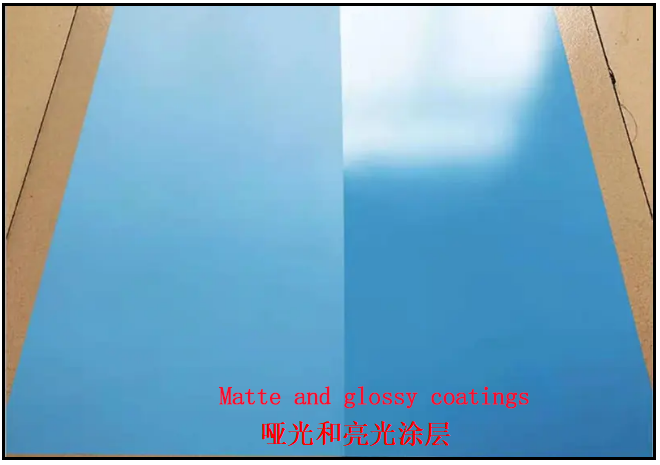

Ultrafine talc has a good thickening effect, and when used in synergy with pyrogenic silica, it can assist pyrogenic silica to form a more branched chain structure, which can effectively improve the utilization rate of thickening and anti-settling effects of pyrogenic silica; at the same time, due to the unique silica structure of ultrafine talcum powder, it has a good dispersion of self-wetting, which can be effectively dispersed to the fineness required by the customers; it can also improve the gloss of the coatings and the flatness of the dry film. It can effectively disperse to the fineness demanded by customers, and improve the glossiness of paint and flatness of dry film.

Ultrafine talc has a certain particle size distribution width, and has the characteristic matting properties of silicate system; fumed silica has excellent matting properties, powder particle size is small, can be directly applied to matte coating system, such as primer, paint and part of the matte topcoat; the two synergistic use of the powder void mosaic is better, and can give play to the better matting properties; in addition, the two main components of the silica, silica hardness and good abrasion resistance, and the two main components are silica. Silicon dioxide has high hardness and good abrasion resistance, and also promotes the coating of scratch-resistant, abrasion-resistant, slippery and other functions.

In the anti-corrosion coating primer corrosion occurs, that is, moisture, as well as sodium, calcium and other ions penetrate and pass through the protective coating process. If the use of polar anti-settling agent or filler, equivalent to the migration of moisture and various types of ions to the metal surface to provide a channel, the moisture accumulated on the metal surface will gradually penetrate into the coating interior, and gradually destroy the adhesion of the coating, which in turn causes osmotic blisters, so that more metal surfaces are exposed to accelerate the rate of corrosion. At the same time, the presence of ions will substantially increase the ionization strength at the interface, accelerating the corrosion rate. The high purity ultrafine talc itself has good hydrophobic properties, and at the same time with the hydrophobic fumed silica, it can effectively close the channels for moisture and ions to migrate to the metal surface, and thus, compared with other types of thixotropic agents, such as treated clay, as well as fumed silica that is not fully hydrophobic, the combination of high purity ultrafine talc compounded with hydrophobic fumed silica, can effectively alleviate the occurrence of corrosion.

In addition, ultrafine talc by its own unique lamellar structure, can give the anti-corrosion coating a certain physical shielding effect, and can be like fumed silica for further hydrophobic modification treatment, to strengthen its hydrophobic properties, better synergistic with the fumed silica to improve the comprehensive corrosion resistance of anti-corrosion coatings.

Conclusion

In summary, ultrafine talc has similar physical and chemical properties with pyrogenic silica, and the oil absorption value is lower than that of pyrogenic silica, add a relatively high proportion, can reduce a certain amount of pyrogenic silica, can also enhance the coating of a certain amount of abrasion and scratch resistance attributes, at the same time to give a matte effect; for the viscosity of the coating system can play a better thickening and anti-sinking effect; in the industrial, anticorrosive and other coatings formulation In the design of industrial, anticorrosive and other coating formulations, often choose to use the two synergistic way of adding to assist the final molding of coating formulations.