Influence of different non-mineral powders and treatment processes on the rheological properties of fluids

As one of the important indicators of fluids, rheological properties directly affect the storage stability and construction performance of adhesives, coatings and inks. Rheological properties are expressed as the relationship between shear force and viscosity, in which viscosity as a measure of fluid flow characteristics of the key indicators, through the measurement of fluid changes in different shear force, can accurately analyze the rheological properties of adhesives, coatings and inks. Powder filler as an important component of adhesives, coatings and inks is one of the factors affecting the rheological properties, and at the same time, the properties are closely related to the type of powder filler, processing technology, particle size and mineral morphology.

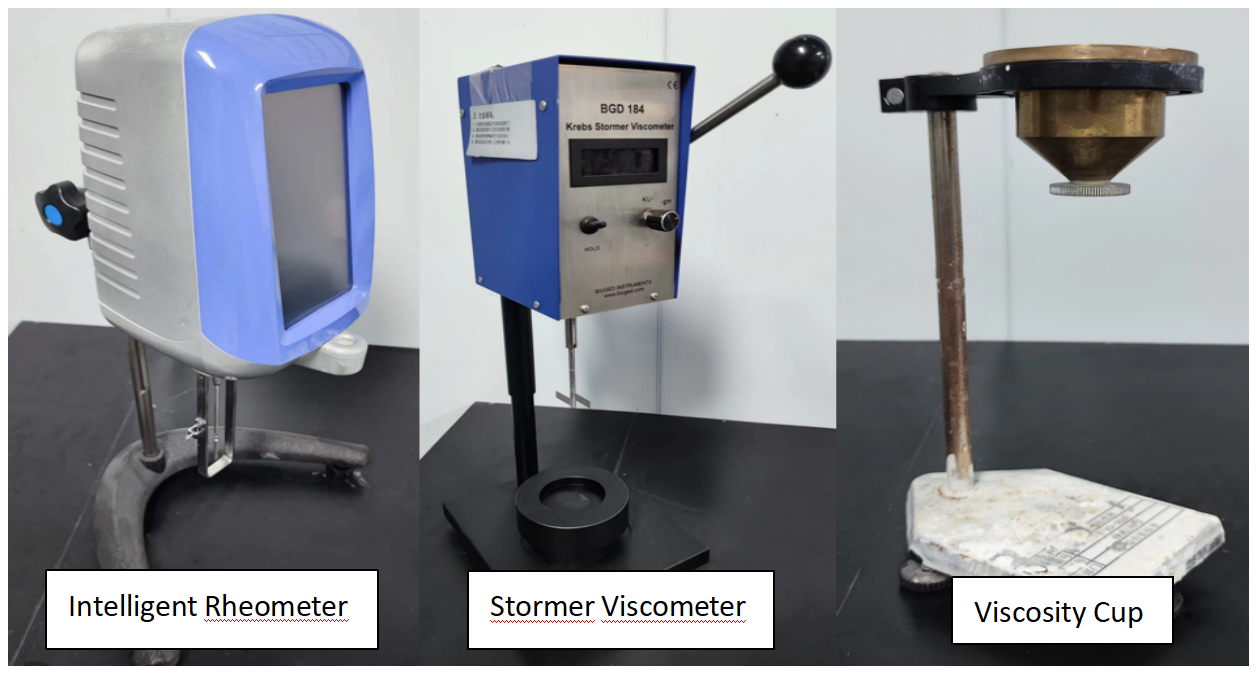

In the actual production of adhesives, coatings and inks, such as viscosity is one of the main control indicators, viscosity is defined as a certain shear rate, the ratio of shear stress and shear rate, the apparent shear viscosity at the shear rate, referred to as viscosity. Common viscosity testing instruments include: rheometer, rotational viscometer, Stormer viscometer, Coat #4 Cup Viscometer, etc. Viscosity and rheological properties of the application, such as: coatings in the storage process hope that the system has a higher viscosity, to prevent the precipitation of pigment fillers; in the construction of the system needs a lower viscosity, conducive to the coating film leveling, this time, if there is a certain degree of rheological properties of the fluid, such as high reduction of low viscosity, high viscosity low shear, it can be a good solution to the problem.

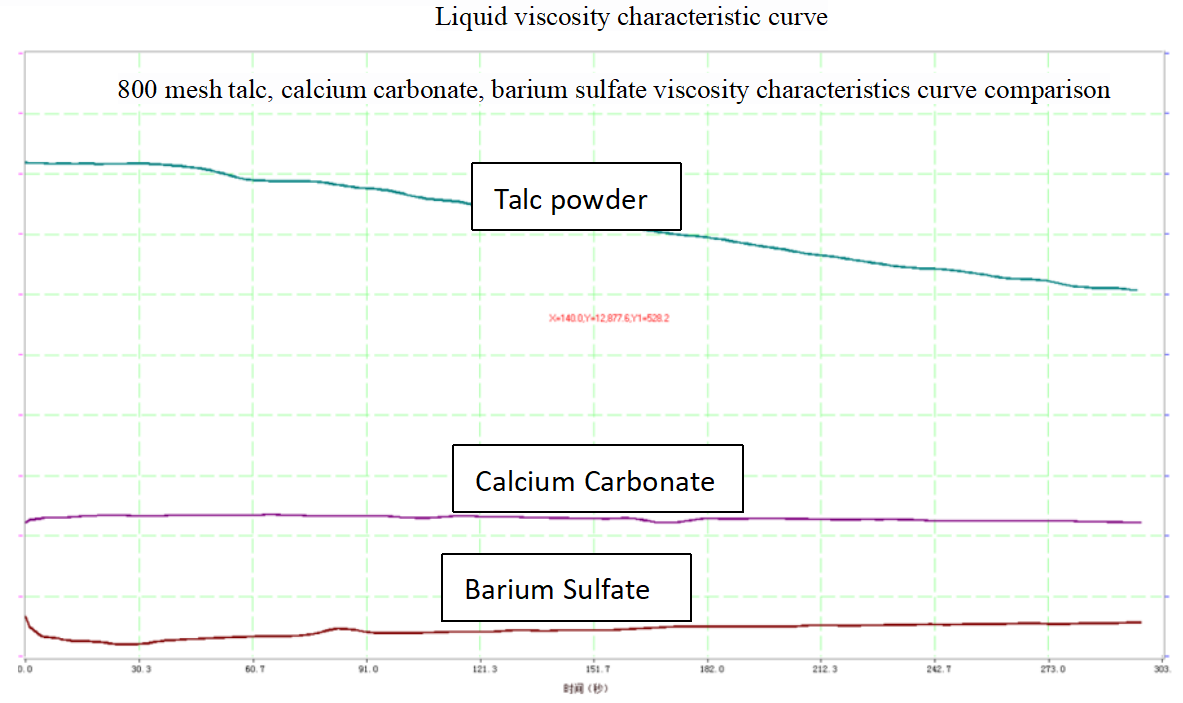

In order to more clearly explain the effect of powder on the rheological properties of fluids, the following rheometer shows the rheological properties of adhesives with different kinds of powders. The following is a comparison of the rheological properties of 800 mesh talcum powder, calcium carbonate and barium sulfate:

The test results show that: the viscosity comparison under the same mesh number, talc>calcium carbonate>barium sulfate. Talcum powder has better thickening properties, and at the same time has shear viscosity characteristics, that is, in the production and storage process is not easy to delamination and precipitation, but also can improve the coating effect, but talcum powder oil absorption value is higher to add too much will lead to the system viscosity is too high, is not conducive to the production and construction; Heavy calcium carbonate rheological properties of the general, viscosity effect is weaker than the talcum powder, but there is a low oil-absorption value, high whiteness, good dry covering and other characteristics, in the adhesive, paint and ink, etc. are widely used; Barium sulfate has very low oil absorption value, compared to other powders on the system viscosity is very low. Barium sulfate has a very low oil absorption value, compared with other powders on the viscosity of the system has very little effect, the theory can improve the filling amount of the powder, but the ratio of the major stability is weak, usually need to be used with additives or thickening type powder.

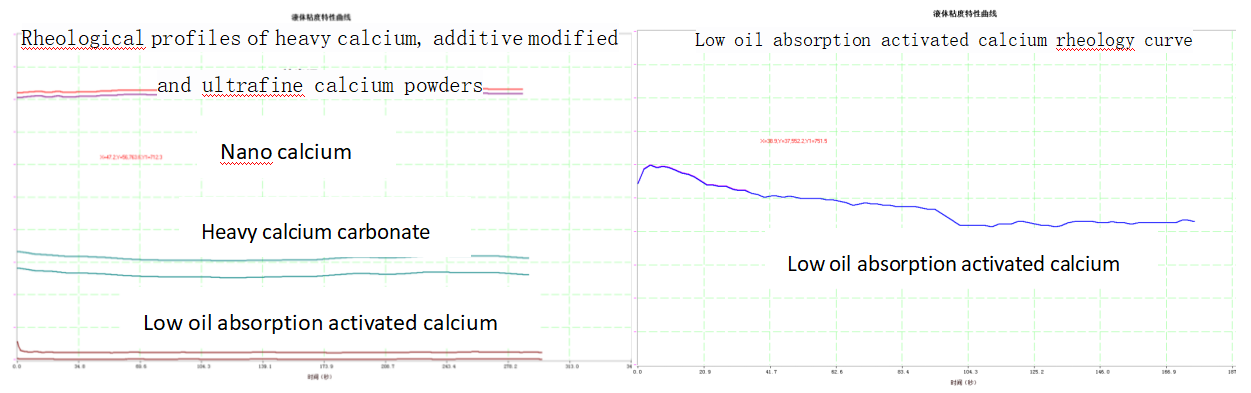

Another for the application characteristics of calcium carbonate, will also carry out different processes to improve the application characteristics of its products, processes such as auxiliary modification and ultrafine processing.

Test results show that: viscosity comparison, nano-calcium > heavy calcium carbonate > low oil-absorbing activated calcium. Generally, the finer the powder, the higher the oil absorption value, the higher the viscosity, by the nanocalcium particle size between 60-100nm, has an excellent thickening effect, can effectively improve the stability of the fluid; at the same time, as can be seen from the above also know that low oil-absorbing activated calcium viscosities are slower than the same proportion of calcium carbonate viscosity, that is, the viscosity of the same additive ratio, and another from the right figure can be seen that the low oil-absorbing activated calcium in a high proportion of the addition of a certain amount of viscosity reduction in shear, similar to the rheological properties of talc, has friendly production and construction characteristics; at the same time, generally with the powder filler, the oil absorption value of the higher viscosity, but also the viscosity of the powder filler. Similar to the rheological properties of talcum powder, it has friendly production and construction characteristics; at the same time, generally with the different additive proportion of powder filler, the viscosity of the system will also appear different changes, and we will follow up on this to start a new share.