Influence of coating system viscosity on filler stability

Coating is a complex mixture containing a variety of components, such as resins, solvents, various types of additives, pigmented fillers and so on. Among them, pigment filler is an important component, which can affect the performance of the coating, the appearance of the coating film and the storage stability of the coating. The viscosity of the coating system is an important factor affecting the stability of the filler.

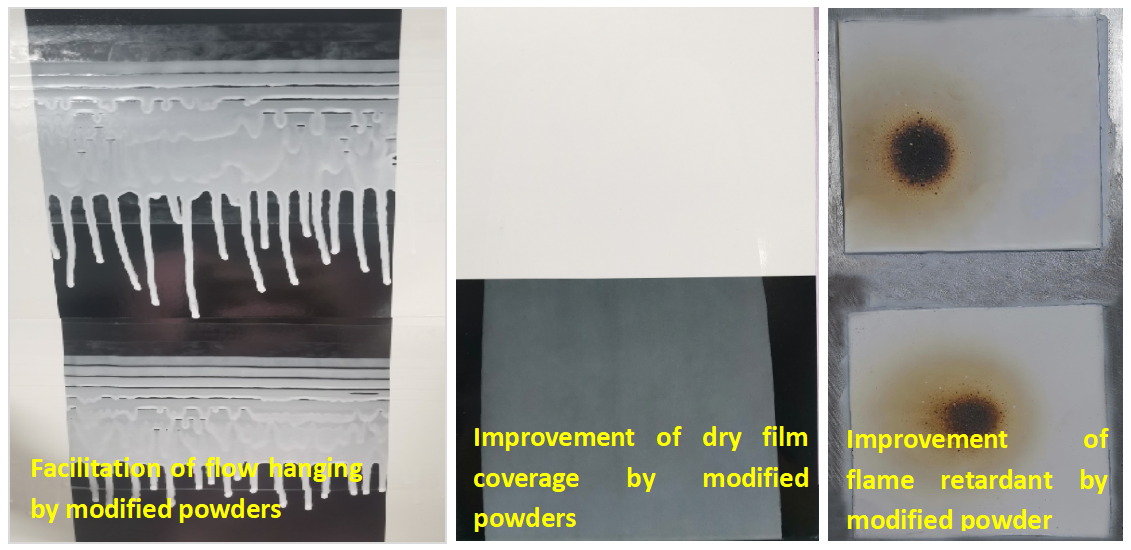

The viscosity of coating system refers to the ratio of shear stress and shear rate of the coating in the flow process, reflecting the degree of coating viscosity and thinning, and is an important parameter of coating flow behavior. There are a variety of means of measurement, such as coating -4 cup outflow method, Stormer rotational viscometer method, etc.; for the viscosity of the coating, there will be construction viscosity and the original paint viscosity distinction, general construction viscosity refers to the use of the working viscosity, the original paint viscosity pointed out that the viscosity of the factory. In the process of coating construction, the construction viscosity will directly affect the coating effect, drying time and film quality; generally low viscosity is favorable to the construction of coatings, which can more easily penetrate into the surface of the coated object while the leveling is better and more uniform in appearance; however, if the viscosity is too low, it may lead to problems such as hanging caused by the coating leveling up too quickly after coating or spraying, which makes it difficult to obtain the required film thickness and uniformity. Therefore, before the construction of the coating, it is necessary to adjust the construction viscosity of the coating according to the characteristics of the coating and the construction requirements.

Viscosity Test Methods | Test Standard | Viscosity range | Application Areas | Characteristics |

Stormer Viscometer Method | GB/T 9269 Determination of Viscosity of Paint Stromer Viscometer Method, etc. | 40~140 KU | Industrial coatings, architectural coatings, etc. | High degree of automation, digital display of viscosity value, easy to operate, and can be used to measure large quantities of products. |

Outflow cup: Law coating-4 cups | GB/T 1723 "Paint Viscosity Determination Method", etc. | 0~150 s | Floor varnish, wood coatings and other low viscosity paint products. | This method is easy to operate and is generally used for measuring low to medium viscosity paint products and for on-site viscosity adjustment. |

Flow out cup method: Example: Cain's cup | ASTM D4212 "Measurement of Viscosity by Immersion Viscosity Cup". | 20~1800 s Selection according to aperture, control viscosity 20~80 s | Measurement of viscosity of paints, varnishes, inks and related liquid materials. | Widely used in the direction of printing inks, etc. |

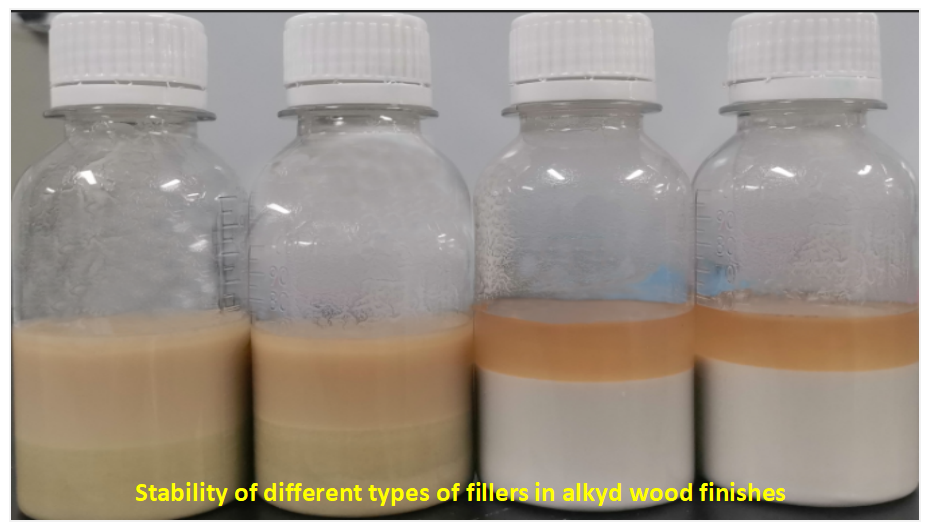

The control of viscosity is not only beneficial to the construction performance of the coating, but also plays an important role in the stability and dispersion of the pigment filler. Generally speaking, pigment filler stability refers to the ability to maintain its dispersion, suspension and uniformity in the coating. The viscosity of the coating system can affect the dispersion and settlement of the filler, thus affecting the stability of the filler. When the viscosity of the coating system is low, the filler is prone to agglomeration and difficult to be dispersed, resulting in the formation of larger particles of filler in the coating, which is not conducive to the use of coatings. Under a certain viscosity, the filler can be better dispersed to avoid the phenomenon of agglomeration, which is similar to the process of pasta. At the same time, when the viscosity of the coating system is low, the filler is easy to settle, and the phenomenon of delamination will occur after long-term storage, resulting in a decline in the performance of the coating. But the viscosity control of coating system is too high and will lead to the formulation, production cost increase, reduce the market competitiveness of the product, so a mature coating products, the control of viscosity is one of the essential links.

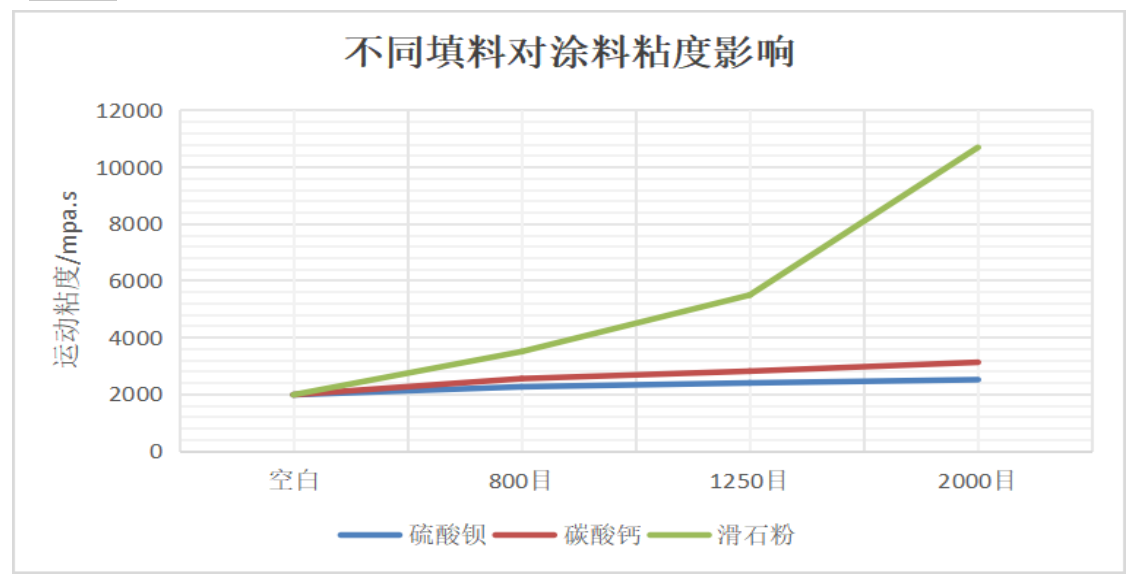

In order to obtain good filler stability, choose the suitable dispersant can reduce the viscosity of the coating and improve its mobility, and make the filler in the coating to get better dispersion and suspension; In addition, the type, fineness and dosage of filler will affect the viscosity of the coating and the stability of the filler, usually the smaller the fineness of the filler, the larger the value of the viscosity of the viscosity impact of the higher, can play a better role in thickening, the better the stability, but the proportion will be limited. Proportion will be limited, at this time you can choose the appropriate mesh filler according to the fineness of the coating scraper and film thickness requirements, to reduce or improve the impact of the oil absorption value on the viscosity of the system; if necessary, for the dispersion of the formulations of the process can also be selected to deal with filler modifiers, additional additives to effect, to improve the dispersion, stabilization, construction, and paint film performance and other characteristics.

Commonly used fillers in the barium sulfate oil absorption value is low, the viscosity of the impact of small but weak stability, usually need to be used with additives or thickening powder dispersion, the overall viscosity and stability is better.

In addition, reasonable grinding process can also improve the dispersion and suspension of filler, and effectively adjust the particle size distribution of filler in the coating system, reduce the occurrence of particles and agglomerates, improve the appearance of the coating spray and fineness. Commonly used sand mills are horizontal, vertical and basket type.

The viscosity of coating system is an important factor affecting the stability of filler. By reasonably controlling the viscosity of the coating system, better filler stability can be obtained, so as to ensure the performance, storage and use of the coating. In practice, we need to adjust the formulation and process parameters according to the different types and uses of coatings to ensure that a stable coating system viscosity and good film performance.