The application difference of different talc powder to coating permeability

Transparent talc is often used in wood primer, adding amounts ranging from 5%-20%, part of the transparent finish can also be appropriate to add; A certain amount of transparent talc can effectively improve the physical and chemical properties of the coating, such as increasing the feel of the paint film surface and effectively improving the sanding property; At the same time, its flake structure, can form a dense isolation layer on the surface of the paint film, improve the anticorrosion of the paint film and use as an auxiliary matting agent. But the general talc transparency is poor, a large number of use will significantly reduce the permeability of the coating.

With the continuous progress of society, people's demand for transparent materials is increasing, and the demand for functional transparent coatings is becoming more and more urgent. The addition of inorganic filler in the formula, not only makes the function of transparent coating more diversified, but also can reduce the cost of transparent resin, more importantly, inorganic filler is easy to be consumed by nature, reduce the pollution to the environment, as environmentally friendly materials.

The commonly used fillers in the formula of transparent coatings are transparent powder, talc powder, silicon powder, etc. Taking wood coatings as an example, transparent powder and transparent talc powder are the most widely used, from primer to top paint can see transparent powder and transparent talc powder using;

Transparent talc is often used in wood primer, adding amounts ranging from 5%-20%, part of the transparent finish can also be appropriate to add; A certain amount of transparent talc can effectively improve the physical and chemical properties of the coating, such as increasing the feel of the paint film surface and effectively improving the sanding property; At the same time, its flake structure, can form a dense isolation layer on the surface of the paint film, improve the anticorrosion of the paint film and use as an auxiliary matting agent. But the general talc transparency is poor, a large number of use will significantly reduce the permeability of the coating.

Transparent powder is often used in high transparency of waterborne wood primer, top paint, can also be used in solid paint, the general amount is between 5%-25%, it has the advantages of low oil absorption, good inertia, high transparency; However, some transparent powder contains crystalline water. If the construction is too thick or excessive, it is easy to cause fog caused by blue light phenomenon. Transparent powder containing crystalline water is easy to lose water and metamorphic moisture absorption, which requires higher storage requirements; Due to its low oil absorption value, poor increase viscosity, and storage easy settlement; At the same time, the paint film is difficult to grind, need to increase a certain amount of grinding agent or filler and other problems; So the use of transparent powder alone, the wood coating formula of the auxiliary collocation and formula debugging has a greater challenge.

In order to improve the use of transparent powder defects, ordinary talc poor transparency and other problems, it is intended to select talc powder of different mineral sources and fineness, respectively add 10%, 15% and 20% in the coating, the coating permeability test, screening transparent grade talc with excellent transparency.

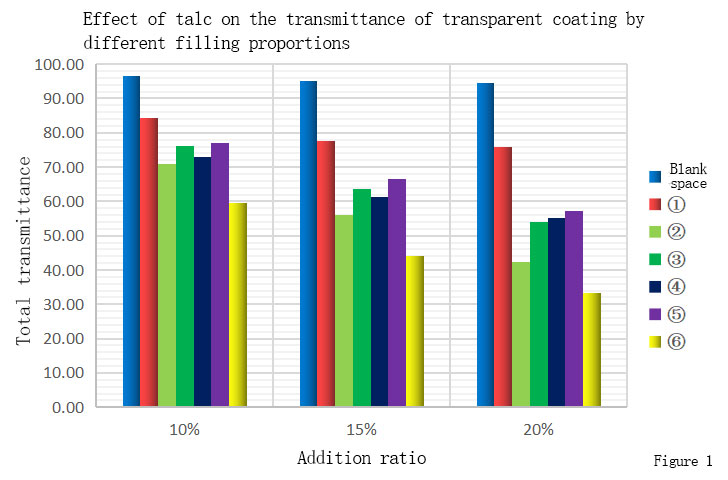

The ISO standard of fog meter is used to test the total transmittance (transmittance) data of different talc coatings under 400-700nm wavelength, as shown in Figure 1. ①Talc added to 20% has significantly less influence on the transmittance of coating, while other talc added to 15% has a significant decrease in transmittance and other problems. ② and ⑥ belong to the covering talc, its transmittance is far lower than that of other talc;

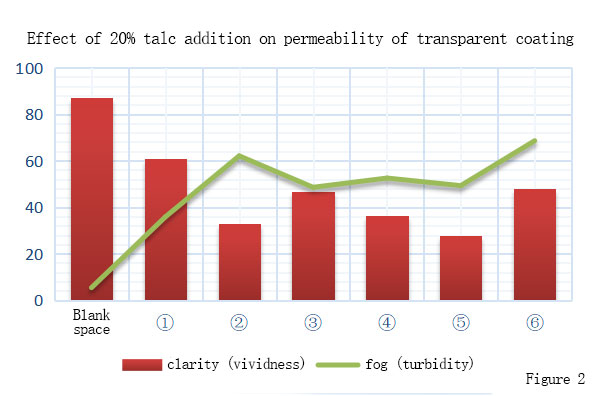

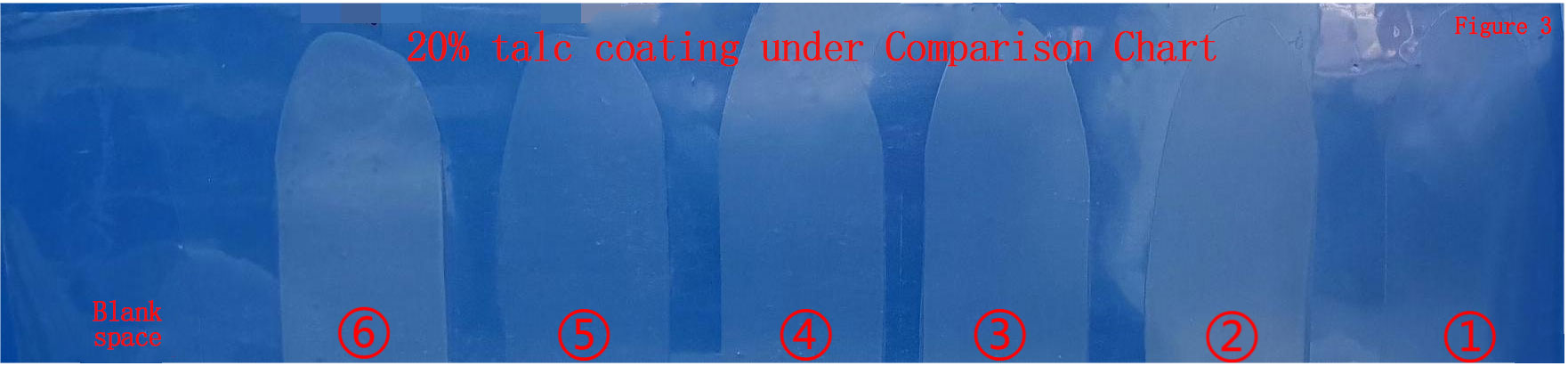

At the same time, the ASTM standard of the fog meter is used to test the fog (turbidity) and clarity (vividness) of the 20% talc coating under the wavelength of 400-700nm, as shown in Figure 2. ① Talc can still maintain good clarity under the 20% addition ratio, which has little influence on the turbidity appearance of the coating; The overall appearance is shown in Figure 3.

To sum up, ① talc has significantly better transparency than other talc, and at the same time, it can still maintain excellent clarity and low fog under a high proportion. It can be seen that ① talc is transparent grade talc, which is more suitable for transparent system such as wood coatings than general talc.